How Acoustic Inspection Services works

This powerful new service uses a directional ultrasonic detector which precisely analyses an acoustic signal from each network asset.

Planning

Detailed planning is all part of the service and includes: health and safety, risk and hazard identification, general survey and close inspection planning, network/fault data, network access and logistics (including landowner permission).

Ground-based survey

Our Acoustic Inspection Services specialise in the inspection of distribution, sub-transmission and transmission overhead networks, substations and ground mounted equipment.

Our team can undertake drive-by inspections (urban and rural) using a state of the art directional ultrasonic detector. In areas with limited vehicle access, inspection can be done on foot. The team can also perform this service from a helicopter where site access is extremely difficult.

Triangulation and identification of defects

Our team of specialist engineers are trained in the identification of ultrasonic defect signatures.

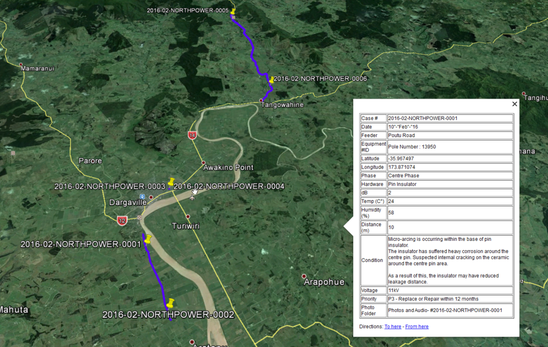

Once detected, triangulation techniques are used to pinpoint the defect location and high-resolution images and data are captured for analysis (including asset information, GPS location, sound power level, sound data file, PD type, environmental conditions).

Our Acoustic Inspection Services found over 10,000 electrical defects across electricity networks, which were previously undetected through traditional inspection methods.

Diagnostics and reporting

Our service doesn't end in the field – our experienced engineering team review the defect data to determine the root cause of problems and to offer potential solutions.

Forensic analysis and diagnosis of defects allows for defect classification and prioritisation in accordance with our customers' network standards.

Defect reports

Defect reports (including defect inspection records, GPS mapping and an inspection database) are prepared for integration into our customers' maintenance management systems (MMS). These reports enable network owners to optimise their asset maintenance and replacement schedule.